There were two major considerations in the design of the final spoil conveyor.

There were two major considerations in the design of the final spoil conveyor.

1. Negotiating model track curves.

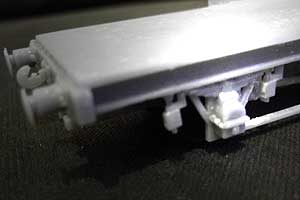

It is obvious that this long conveyor sticks out a long way from the rear of the wagon. If the conveyor was fixed in position then, with the wagon in transit and moving around track curves especially the tight curves of model railway track, it would swing out beyond loading gauge limits and potentially hit a train on an adjacent track. Therefore, I had to make it swivel (as the prototype) so that it can be constrained within the width of the wagons. An added complication is the hopper that feeds this conveyor. It cannot be fixed to the conveyor. We can see the split line in the photo that allows the conveyor to swivel independently of it.

When designing the conveyor I had to ensure its height kept within the loading gauge and ensure there was no interference with parts of the generator wagon. These constraints set the length of the conveyor.

The conveyor rests on a yoke frame. I raised the ends of this to limit travel of the conveyor as the train negotiates track curves. I am pleased to say that the swivelling conveyor works as planned around the tightest curves of my model railway layout.

2. Interaction with the Power Generator Wagon

As explained, the conveyor rests on the Generator Wagon during transit. Well, that is how it was in the early days. Later on the machine was supplied with a match truck where the conveyor rested on that instead.

I digress here to explain the orientation of the two wagons. In the photo above the arrangement is for transport. For working activities the power generator wagon is run around the other end of the machine and a high voltage umbilical cable connected between the cabins.

Whilst I digress, how does the ballast cleaning machine move when working? Beneath the buffer stock at the spoil conveyor end is a drum winch with two cables. The cables may have been bolted to the fishplates or chairs of the railway track and the machine winched itself incrementally along. Another oddity is the braking arrangement of the machine. I have found no evidence of brakes or vacuum pipes on this early machine. Maybe the red handles beneath the cabin operated brakes(?) What there is is a long pipe that runs along the girder frame to the buffer stocks at each end. I guess that connected to the pipes of adjacent wagons?

Now, there are subtle differences between between builds of this Matisa 3B5 machine and the generator wagon variant I choose to model seems to be a latter variant that did not support the conveyor (match truck used instead?). Consequently that big box on the end of the wagon causes the conveyor to lift higher than desired and this lead to it being shorter that in should be. The variant I should have modelled did not have the big box. Instead it had two fuel drums laid down and further inboard that would allow the conveyor slope to be less and its length longer so that it sat correctly above the generator unit instead of in front of it.

In Conclusion

I had hoped to get the design of these models right first time but, I'm afraid I have not. I have a list of 10 faux pas of which the most significant is the girder frame that should have been set further in board. Correcting this will have knock on effects of many other parts. Modelling the wrong generator wagon variant is also disappointing. Also, I am unhappy with the quality of 3D print. It all looks a bit rough on close inspection. Nevertheless, when I placed the models on my scenic model railway they certainly look the part and we do not notice the rough finish as much. So, I am encouraged to carry on with this project.

What I will do is overhaul the CAD design to correct errors and add more details with a view to Resin 3D printing in the future for greater finesse of the models.

Next though I must prepare the Grampus wagons.

To Part 9.

To Part 1.