This is the Airfix 1:43 scale Land Rover Series 1 kit released 4th quarter of 2023. The Series 1 was manufactured by Land Rover from 1948 to 1958 so, I thought it would be a nice addition to my Corona Quay layout, set in the early 1960s.

I did not intend this to be a kit review but there were some issues that you may wish to consider if wanting one. Never the less it is an easily assembled kit delivering a fine looking model.

This Airfix kit, whilst highly detailed in parts, has some notable exceptions. Being a 'Starter' kit for novice constructors this may be excusable but there is one glaring omission that is highly visible on the prototype. More on that latter.

The components are weakly mounted on the sprues and can be easily knocked off and lost. This happened to me as after washing in soapy water, as instructed, I noticed one component was missing from the sprue. The front axle is a two part assembly, I only had the lower part that does not have the axle stubs for fitting wheels. I can only assume the missing part containing the axle stubs was sent down the sink plug hole! I remade the missing part from a wooden cocktail stick.

I used the paints from the kit. The body colour provided looked white to my eye. It should be light grey so, I added a small amount of black to the pot. By the way, red for the rear lights is not provided.

About the kit omissions, I'll start with the cabin.

The three gear levers are not included in the kit and the footwell moulding has no foot pedals. The later, if it was provided, cannot be seen after assembly so its absence is of trivial concern, except for the purist modeller of course! I decided not to fabricate pedals.

The gear levers I did make but, even these are not noticeable unless the cabin is lit with LED or sun. All levers are made from 0.5 mm diameter wire. The knob on the longest lever was fettled from kit sprue and the two smaller ones were made from a drop of superglue on the wire end and then dipped into bicarbonate of soda to solidify and bulk up. (Note: The 'yellow' lever was a later addition to Land Rover's range).

Next is the exhaust pipe.

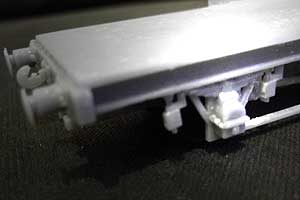

This really should be part of the kit as it is highly visible on the prototype. There are a couple of holes in the chassis frame that look as though they are for a pipe to feed through since they serve no purpose in the standard kit. If they are for an exhaust pipe then one is in the wrong place because the pipe bends to the side of the landy in photos I have seen and not out the rear. That hole can be seen in the photo.

I made the pipe from sleeved solid wire with the wire pulled back a bit to reveal the open end of the sleeve. The two silencer boxes were provided by slipping over a sleeve taken from thicker wire.

Finally the wing mirror.

A brochure from the period shows a single wing mirror on the drivers side. It may be that not all landys of the period had wing mirror(s). The prototype in the photo on the Airfix box does not have one.

But, since I was having fun making the previous missing parts I decided to continue to make a wing mirror, fabricated from wire and kit sprue. The mirror itself being silver paint.